In any ceiling project, the choice of batten material plays a big role. Some may look at the price first, but the real impact goes beyond cost. Battens support the ceiling and keep it aligned. They must stay strong, hold up over time, and meet safety rules. Timber and metal battens each have their own features. Some work better in dry areas, others suit wet or fire-prone places. Picking the right type helps avoid future issues and keeps the ceiling stable for years.

What Are Ceiling Battens?

Ceiling battens are slim strips fitted snugly between the buildings frame and the visible ceiling. They to form a small gap that the ceiling sheet rests on. That gap promotes airflow, hides cables, and wires, and keeps the finish looking tidy. By providing steady contact, battens keep the ceiling flat over years of temperature shifts. Remove them and the lining risks drooping or twisting.

Primary Functions of Ceiling Battens

First, ceiling battens carry the ceiling sheets weight. They spread that weight across several points instead of letting it hang from a single beam. The gap between each batten also invites air to slide around, pulling away excess moisture during humid spells. In rooms that cool and warm quickly, less trapped water means fewer stains and decay. Because battens are spaced carefully, large ceilings stay straight, smooth, and free of ripples.

Common Applications in Modern Construction

On jobs big and small, builders reach for ceiling battens inside homes, offices, shops, and transit terminals. You will see them above living-room dining-room ceilings and also overhead in wide auditoriums. Carpenters attach plasterboard, timber panels, metal grids, or other finishes directly to the running strips. Designers lean on the uniform lines battens give when sketching modern, minimalist looks. In addition, many testing labs report that a battened ceiling absorbs sound better and resists flames longer.

Material Comparison Overview: Timber vs. Metal Ceiling Battens

Timber and metal battens are both used to support ceiling systems. They often look similar in size and shape, and they are fixed in similar ways. But they are very different in how they perform. Each type reacts in its own way to heat, moisture, weight, and age. The choice between timber and metal depends on what the project needs. Some sites need materials that resist fire. Others need products that last longer in wet or humid places. Some builders want something fast to install. Others care more about long-term value. By looking at the main features of each material, it becomes easier to choose the right one for the job.

Core Differences at a Glance

| Feature | Timber Battens | Metal Battens |

| Durability | Can rot, warp, or split over time | Stays straight and stable for many years |

| Moisture Resistance | Absorbs water, may swell or decay | Resists water, does not swell or rot |

| Fire Resistance | Burns easily unless treated | Non-combustible, safer for fire zones |

| Weight | Heavier and harder to handle in bulk | Light and easy to move or lift |

| Installation | Easy to cut but may vary in size | Pre-sized, faster to align and fix |

| Maintenance | Needs regular checks and treatment | Little to no maintenance once installed |

| Cost (Initial) | Often cheaper upfront | Higher cost at first |

| Cost (Long Term) | May need repairs or replacements | Lower lifetime cost due to long life |

| Recyclability | Biodegradable, not always reusable | Fully recyclable, good for green projects |

This table helps show how timber and metal battens work in different ways. Each has its place, but metal is often the better fit for commercial or long-term projects.

Timber Ceiling Battens: Traditional Strengths and Modern Limitations

Timber has been used in ceiling systems for a long time. It is a common choice because it is easy to find and simple to work with. Many builders know how to handle timber. They can cut it, nail it, or screw it with basic tools. It also feels familiar in both small homes and large buildings. But in today’s construction world, timber battens show more limits than before.

Advantages of Timber Battens

Timber battens are simple to work with on-site. If a length is too long, a crew member just picks up a saw and trims it. Wood also grips nails and screws better than most modern boards. That, paired with its warm colour, is why many designers still choose it. In a dry indoor climate, untreated timber can keep going for years. It even offers a little sound proofing and mild thermal insulation, so rooms feel cozier.

Limitations of Timber in Contemporary Construction

Yet timber comes with a long list of downsides. It soaks up water, then swells, cracks, or splinters. Add constant dampness and the whole piece may start to rot. Termites, fungus, and even simple mould can feast on untreated boards. When heating kicks in and the air goes dry, wood shrinks and twists unpredictably. Being so combustible, it worries anyone following strict fire codes. All these factors keep timber out of many commercial and long-life projects. A contractor ends up checking, treating, or swapping parts far more often, and that drives costs up fast.

Metal Ceiling Battens: The Modern, Performance-Driven Alternative

Metal ceiling battens have become a trusted option on countless construction sites. Crafted for straight edges and tough performance, they resist the warping that often troubles wood. Because of these qualities, contractors favour them in offices, malls, and public venues, and they shine in spaces where humidity or fire risk is high. Unlike timber, metal battens hold their shape indefinitely, making them ideal for ceilings that must look flat and stay sturdy over time.

Advantages of Metal Battens

Because they dont burn, metal battens help projects pass even the toughest fire codes. Their light weight speeds handling and lets teams cover big areas without tired arms. Once factory-coated, the surface ward off rust and laughs at damp air. Even months later, they remain straight; no twisting shows up after the screws are driven home. The long, sharp lines they leave on ceilings suit modern, minimal designs perfectly. At decon, every scrap can be sent back to the mill, cutting landfill load for builders who care about the planet.

Potential Drawbacks of Metal Battens

Metal battens cost more at the start. This can affect project budgets, especially in small builds. They also carry heat, which may matter in ceilings near hot pipes or roofs. Installing metal battens takes care and planning. The cuts must be clean. The spacing must be right. But with the right tools and training, the process is fast and smooth. Many builders now see the long-term value in metal, even with a higher upfront price.

Installation & Labor: Which Is Easier on Site?

The speed and ease of installing ceiling battens can affect the whole job. Labor costs rise when materials take more time to measure, cut, or fix. The smoother the process, the faster the ceiling is ready for the next step. Both timber and metal have their own ways of being handled, but not all materials save time in the same way.

Working with Timber on Site

Timber is simple to cut. Workers only need basic tools like saws or drills. Many builders already know how to work with it, so training is not needed. But timber pieces are not always straight. Some are slightly bent or uneven. This makes it harder to line them up. Workers may spend extra time checking levels and adjusting. Some timber also cracks when nailed, which leads to waste. These small issues add up and slow down the job.

Installing Metal Battens Efficiently

Metal battens are made in exact sizes. They are light and easy to move around, even on tall ceilings. Most come with pre-punched holes, so workers can screw them in quickly without measuring. The straight shape helps keep the ceiling flat without much checking. There is less waste because the pieces do not split or bend. For big projects with tight deadlines, metal battens help save time. Even if workers need a bit of training, the job goes faster once they get used to the system.

Fire Safety & Compliance: Why Metal Often Wins

In most offices, hotels, schools, and public halls, fire safety comes first. As authorities raise the bar, more new buildings must use materials that resist flames completely. The ceiling structure is part of that picture. If an outbreak occurs, the grid of cross rails and battens should neither feed the fire nor lose strength too quickly. Because of this, every specifier pays close attention to the batten chosen.

Fire Ratings of Timber Battens

Although timber is beautiful and easy to work with, it is still wood and will burn. Without special chemical impregnation the boards ignite quickly and release smoke. To satisfy todays codes contractors normally specify a high-VOC exterior-grade lacquer, yet even such coatings degrade over time under light, heat, and humidity. Where extra safety is demanded the battens end up sandwiched behind weighty gypsum or mineral-fibre panels, adding cost, labour hours and ceiling depth. For corridors, atria or basement plant rooms that risk hotline the treatment chain still leaves room for concern.

Inherent Fire Resistance of Metal

Steel and aluminium will not catch flame. Both metals retain most of their mechanical strength minutes after a blaze starts, giving occupants precious extra minutes to escape and heroes time to fight the seat. Factory-finished painted metal battens routinely receive Euroclass A1/A2 ratings, so specifiers rarely need add a layer of still more paint or board. A single assembly can be hung faster, with fewer fixings, and offers no food for pests. For critical infrastructure-galleries, hospitals, tunnels, high-rise lobbies-the long-term certainty of metal battens often settles a debate that timber continues to open.

Cost Comparison: Upfront vs. Lifecycle Value

Price is one of the first things most builders look at. Timber battens usually cost less at the start.That makes them a favorite for projects where money is tight. Yet the true price of a ceiling system goes beyond the shopping list-it also includes installation hours and how well the assembly stands up in the years ahead. Metal often shines in these long-term tests, showing better value overall.

Initial Material and Labor Costs

Timber battens carry a lower tab when you look at the store receipt. They are everywhere, and just about any crew can cut, drill, and nail them into place. Because lumber is rarely perfectly straight, though, teams spend extra time shimmying, leveling, and double-checking. On top of that, some boards need to be swapped out during or even before the build. These little headaches drag out the schedule and quietly push up the labor bill.

Long-Term Value and Maintenance

Metal battens cost more at checkout, yet their service life far outlasts almost any other option. They wont rot, swell, or warp, and they brush off water in ways wood simply cant match. Once the last screw is poured, everyday care shrinks to a light wipe now and then, and thats about it. Because of that, teams spend less time on-site, repairs pop up far less often, and total replacement stays off the table for many years. When the math is run decades later, savings in labor and routine fixes typically outrun that higher starting price. For builders chasing results that really stick around, metal tends to be the smarter call.

Environmental Considerations: Sustainability and Lifecycle Impact

Sustainability sits near the top of every contractor s list these days. Building crews no longer track success by speed and cost alone; they also watch carbon tallies and resource flows. From the first sketch to the last tear-down, every material call can tip the scale toward a greener finish-or away. The choice between timber and steel ceiling battens sits squarely in that picture.

Is Timber Truly Eco-Friendly?

Timber carries a reputation as the warm, natural option that Mother Earth herself would approve. That reputation holds true only when boards come from responsibly managed forests and within time- tested replanting schemes. Unfortunately, a surprising amount of lumber still enters the market after passing through weak or unaudited chains-of-custody. Add the spoil that arises on site-warped brackets, broken splits, even minor off-cuts-and the perceived environmental gain quickly begins to erode. When life ends, coated, glued, or treated battens face long landfill stays instead of being reborn, locking carbon away for decades.

Recyclability and Longevity of Metal Battens

Metal battens are strong and last a long time. When the ceiling system is removed, the battens can be recycled. They do not go to waste. The metal can be melted down and reused for new products. This helps reduce raw material use. Builders who use metal battens can earn points for green building certifications like LEED. This matters for government or public projects. Long lifespan also means fewer replacements and less waste over time. Metal supports both durability and environmental goals.

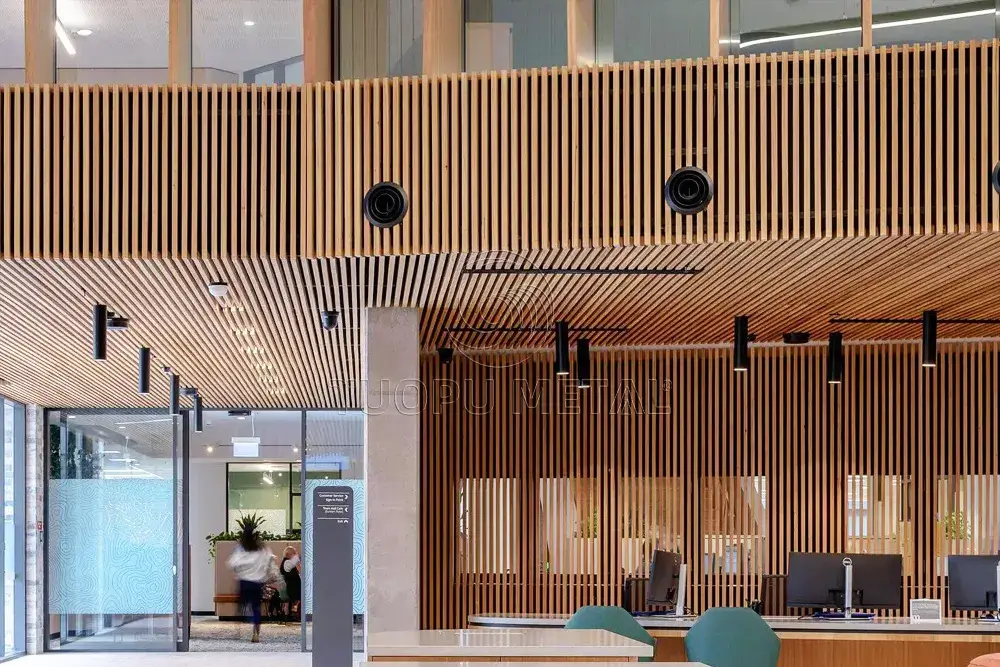

Why More Designers Are Switching to Metal Ceiling Battens

More designers are choosing metal ceiling battens today. They want materials that last longer and need less care. Metal battens meet strict building rules without extra treatments. They hold up well in wet or fire-prone areas. Metal also helps create clean, modern ceiling designs that many clients like. With fewer problems during installation and less need for repairs, metal saves time and money in the long run. These benefits make metal battens a smart choice for projects focused on quality and durability.

Which Ceiling Batten Is Right for Your Project?

Selecting a ceiling batten goes beyond grabbing the least-expensive pack at the store. You really ought to consider how the space will be used, any local codes, and the lifetime you expect from the ceiling. Timber battens still shine in quiet, dry rooms where the fire load is low and beauty is a priority. Metal battens start to steal the show when you need heavy-duty strength, solid fire behaviour and almost-zero upkeep. Designers and contractors alike should add up those angles before hitting the buy button. Get it right and the ceiling stays snug, safe and smart-looking for years. That, in turn, cuts callbacks, protects budgets and keeps everyone on-site happy.

Explore Tuopu Metal Custom Ceiling Batten Solutions

Tuopu Metal’s line-up of metal ceiling battens covers a huge range of jobs and styles. From elegant baffle ceilings to slim strip versions, each piece leaves the factory only after passing strict quality checks. Buyers can pick the exact profile, length and finish that suit their vision, whether matte black or brushed aluminium.

Tuopu Metal Building Materials Co. Ltd has the solution if you are a contractor, designer or even a business owner looking for expert advice regarding custom ceiling batten solutions. Reach out to us and we will be glad to provide you personalized suggestions along with quality products to cater for all of your needs for commercial projects. Let’s collaborate and turn your vision of creating spaces that are functional while being eye-catching into a reality.